Precision Solutions Made in GermanyRotary Servo Motors for High-Precision Tasks

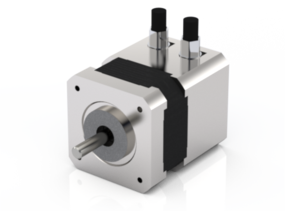

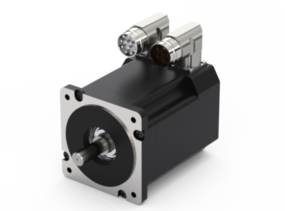

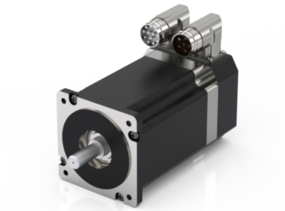

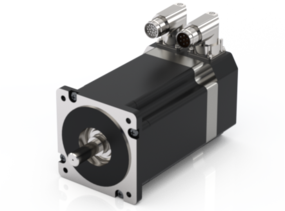

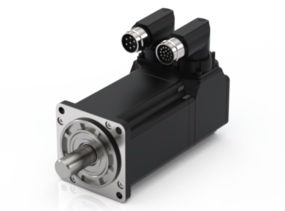

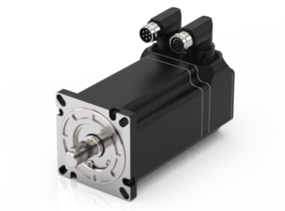

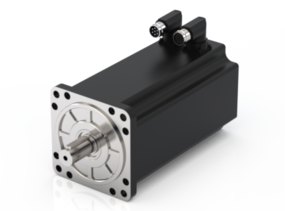

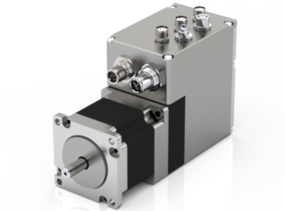

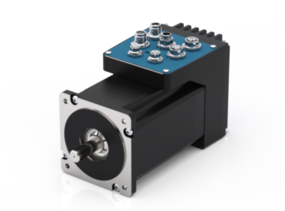

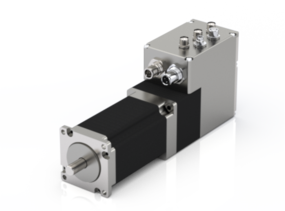

JAT rotary servo motors provide precise, repeatable motion for demanding positioning and handling tasks. The portfolio covers multiple performance classes and flange sizes from 42 to 150 mm. Motors are available with various encoder types and cable options so that each drive train matches the specific machine concept.

We offer explosion-proof servomotors (ATEX), certified according to ATEX II 2G Ex d IIB T4 Gb and IEC / EN 60079-1.

Our flexibility allows us to provide the exact electric motor adapted to your functions and use. Examples of customer-specific motor adaptations show the many options for implementing customer requirements, from custom windings to unique mechanical interfaces.

Find out in just 15 minutes how we can optimize your processes, free of charge!

Unfortunately, we do not currently have a motor in our product

range

that meets your

requirements.

However, one of our strengths is the realization of

customer-specific

products and solutions, so

that it

is always worth contacting our drive experts.

ontact now

Why JAT Servo Motors?

Engineers and procurement officers choose JAT because we solve the specific technical challenges that standard catalog motors cannot.

Customization from Quantity 1:

We adapt motor windings, shafts, and flanges to your machine, eliminating the need for costly design workarounds.

Direct Drive Expertise:

Our ECOSTEP technology provides high torque at low speeds, often removing the need for gearboxes and increasing overall system precision.

Total System Integration:

We provide perfectly matched drive trains, including motors, servo amplifiers, and intuitive commissioning software.

Electrical Adaptation:

We optimize motor windings for specific DC link voltages from 24 to 560 V DC to maximize efficiency in battery-powered or high-voltage applications.

Select by Technology

We categorize our rotary motors by their physical operating principle to match your specific application needs.

ECOSTEP: High Torque without the Gearbox

The ECOSTEP principle uses high-pole synchronous motors with encoders and sinusoidal commutation. These motors are designed for high dynamics in the typical speed range up to 1,000 rpm.

Positioning Accuracy: Eliminating the gearbox removes mechanical backlash and maintenance requirements.

Efficiency: ECOSTEP motors offer lower power loss during continuous start and stop cycles compared to standard AC servomotors of similar size.

ECOSPEED: Maximum Dynamics and Synchronization

The ECOSPEED series is optimized for high-speed performance and extreme synchronization accuracy.

High Speed: Achieves speeds up to 8,000 rpm.

Robust Protection: Standard IP65 rating ensures resistance against dust and water jets in industrial environments.

Interfaces

Pair the motors with JAT servo amplifiers for precise positioning and reliable commissioning. Feedback and cabling options are matched to the drive families to simplify wiring and setup. See Servo amplifiers category for controller selection and interface details, then request a concept for your machine.

Can’t find the exact motor for your requirements?

Looking for a motor that fits your machine exactly? Our drive experts assist you from initial conception to final commissioning. We analyze your requirements to find the most efficient and cost-effective drive solution.

Request a potential analysis or ASK ENGINEERING