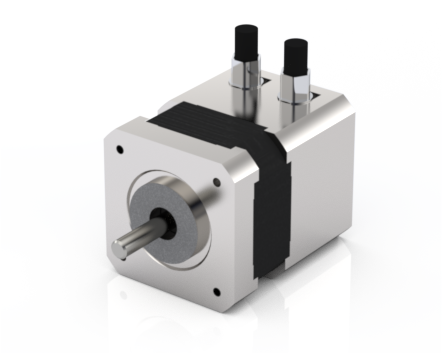

ECOSTEP 17H19-0230 compact NEMA 17 high torque servo motor

Technical specifications

| Flange | 42 mm |

| Max. DC link voltage | 60 VDC |

| Maximum speed | 3000 rpm |

| Peak torque | 0.55 Nm |

| Stall torque | 0.37 Nm |

Overview

The ECOSTEP 17H19-0230 is a compact rotary servo motor in the ECOSTEP 17H series for dynamic, high precision positioning where installation space is tight but torque demand is higher. It keeps the 42 mm NEMA 17 flange and extends the housing length to 68 mm, with a motor mass of about 0.4 kg, so you gain more torque in the same footprint.

Designed with power based on torque, the motor offers 0.15 Nm rated torque at 2000 min⁻¹ and about 31 W rated power at 60 V DC, giving you strong performance at the operating point. Standard protection is IP40, with an IP65 housing option for harsher environments, while the shaft gland remains IP40. Configuration options include different encoder variants, an optional holding brake, gear variants and predefined connector and cable sets for straightforward integration with JAT servo amplifiers.

Advantages

The ECOSTEP 17H19-0230 provides more high torque NEMA 17 servo motor performance in the same 42 mm flange size.

- When high torque at low speed and precise control are required, ECOSTEP motors provide a cost-efficient alternative to traditional servo motors.

- Compact and powerful: higher maximum torque in relation to motor size for demanding small rotary axes.

- Direct drive capable: sufficient torque at low speed can let you omit a gearbox, which helps reduce backlash and mechanical complexity.

- High dynamics: genuine servo operation supports dynamic start stop motion and repeatable positioning.

- Adaptable to the application: various mechanical options and winding adaptations allow optimisation of the operating point from quantity 1.

Where it fits

Use this compact rotary servo motor where space is limited but loads and dynamics are higher than with the shortest 17H variant:

- Small pick and place axes and light handling units with higher torque demand

- Indexing and format adjustment axes in compact machines

- Rotary actuators in laboratory, analysis or inspection equipment

- Fine adjustment stages and positioning systems in optics and precision mechanics

Interfaces

The ECOSTEP 17H19-0230 supports 24 to 60 V DC link operation and integrates cleanly into JAT drive systems.

- Feedback: incremental ABN encoder as standard with 4000, 8000, 40 000 or 160 000 increments per revolution, higher resolutions up to 256 000 inc/rev available on request

- Options: integrated holding brake with 0.30 Nm braking torque, IP65 housing option, gear variants and tailored cable lengths

- System integration: predefined connector and cable options and matching connector sets are available for ECOVARIO 114D, ECOMODUL and ECOMiniDual servo amplifiers, which simplifies wiring and commissioning and helps the motor achieve its specified performance in JAT drive systems