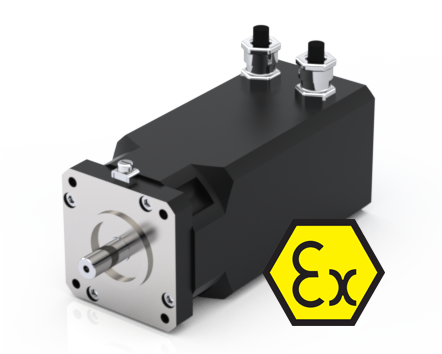

ECOSPEED 80B343-0360 ATEX, high torque servo motor for Zones 1 and 2

Technical specifications

| Certificates | Atex , UL |

| Flange | 88 mm |

| Max. DC link voltage | 560 VDC |

| Maximum speed | 5500 rpm |

| Peak torque | 11.71 Nm |

| Stall torque | 4.2 Nm |

Overview

The ECOSPEED 80B343-0360 ATEX is a high torque rotary servo motor for potentially explosive gas atmospheres in Zones 1 and 2. It combines an 88 mm flange, max. DC link voltage of 560 V DC, maximum speed of 5500 rpm, 11.71 Nm peak torque and 4.2 Nm stall torque, so it delivers strong rotary power in a compact footprint.

As part of the ECOSPEED 80B3x3 ATEX series, the motor sits in a platform with design voltages from 60 to 560 V and speed ranges from 1400 to 7000 rpm, depending on the variant. The series is built around a flameproof enclosure Ex d with ATEX II 2G IIB T4 certification and also carries UL approval, which supports use in international projects and simplifies approvals in regulated industries.

Advantages

The ECOSPEED 80B343-0360 ATEX is designed for engineers who need both documented explosion protection and strong dynamic performance on a single axis.

- Certified for Zone 1 and Zone 2

ATEX II 2G Ex d IIB T4 and UL certification provide the formal basis for using this motor in plants with flammable gases or vapors, which reduces effort in risk assessments and technical documentation for hazardous areas. - High torque with compact footprint

With 11.71 Nm peak and 4.2 Nm stall torque on an 88 mm flange, the motor offers significant torque reserves for starting, indexing or clamping moves without moving to a larger frame size. - Platform flexibility

The 80B3x3 ATEX platform supports 60 to 560 V and up to 7000 rpm, so you can standardize around one hazardous area motor family across different machine concepts and supply levels. - Integrated feedback and monitoring

Multiturn absolute encoder options with 13 bit singleturn and 12 bit multiturn resolution plus an integrated PTC temperature sensor support precise position control and thermal protection through the servo amplifier.

Where it fits

The ECOSPEED 80B343-0360 ATEX is suitable wherever high torque, medium to high speed motion is required in explosive gas atmospheres, for example:

- Agitators and mixers in chemical or coating processes where powerful, controlled rotation is needed in Zone 1 and Zone 2.

- Rotary indexing axes in filling, dosing or packaging equipment with solvent based or flammable media.

- Drive modules on process skids in oil and gas or chemical plants where 560 V DC link systems are standard and installation space is limited.

In these applications, the motor offers a servo grade alternative to pneumatic or hydraulic drives, with better positioning and repeatability while keeping the explosion protection level.

Interfaces

- Power interface

Three phase servo motor connection for max. 560 V DC link operation, matched to high voltage ECOVARIO servo amplifiers in the appropriate power class. - Feedback and monitoring

Multiturn absolute encoder options with 13 bit singleturn and 12 bit multiturn resolution, 10 to 30 V supply, with BiSS or SSI interface depending on the selected variant, plus an integrated PTC temperature sensor for winding temperature monitoring via the drive. - Mechanical interface

Flange 88 mm and shaft diameter 14 k6 for easy coupling to gear units, rotary tables or direct driven mechanisms, with axial and radial load capacities sized for typical loads in this torque class. - Cabling options

Trailing capable motor cable around 8.9 mm diameter and encoder cable around 10.4 mm diameter with defined minimum bend radii for use in drag chains, as specified for the 80B ATEX family.