ECOeasy, 1-axis Servo Ampliefier, 20 - 60 VDC

Technical specifications

| DC supply voltage | 60 VDC |

| DC link voltage | 60 VDC |

| Number of axes | 1 |

| Power category | 1 kW |

| Max. output current | 15 A |

Overview

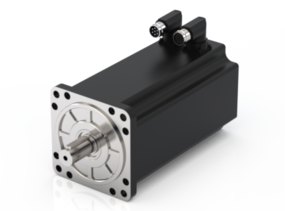

The ECOeasy is a compact, high-performance single-axis servo drive designed for modern industrial motion-control applications. It combines maximum flexibility with easy system integration and is ideally suited for OEM machines where fast adaptation without hardware redesign is required.

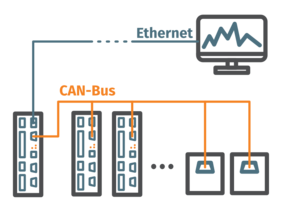

With integrated support for modern fieldbus systems such as EtherCAT (EoE), Ethernet/IP, and PROFINET, as well as a comprehensive I/O configuration, the ECOeasy offers a wide range of communication and control options. The ECOmotionSuite enables intuitive commissioning, parameterization, and diagnostics directly on the system.

Thanks to its compact design, the ECOeasy fits easily into space-constrained control cabinets without compromising performance or functionality. With a continuous current of at least 10 Aeff and a peak current of 15 Aeff, it delivers stable and highly dynamic motion control for demanding single-axis applications.

Functional safety is an integral part of the ECOeasy. With certified STO functionality up to SIL 3 / PL e, it meets the highest safety requirements for modern automated machinery.

Why ECOviva?

- Flexible firmware customization: Application-specific technology functions can be integrated directly into the firmware.

- Wide fieldbus support: EtherCAT (EoE), Ethernet/IP, and PROFINET ensure future-proof connectivity.

- Compact housing: Small dimensions (approx. 154 × 32.5 × 105 mm) enable flexible installation.

- Robust performance: Minimum 10 Aeff continuous current and 15 Aeff peak current for reliable motion control.

- Comprehensive I/O options: Digital and analog I/Os for seamless system integration.

- Easy commissioning: Fully compatible with the ECOmotionSuite for fast setup and diagnostics.

- Certified safety: Integrated STO safety function up to SIL 3 / PL e.

Applications

- Inspection: Precise and synchronized axis control for inspection and measurement systems

- Pick & Place: Efficient handling in coordinated multi-axis systems

- Focus & Dispensing: High-precision positioning and material application

- Marking & Cutting: Accurate motion control for marking and cutting processes

- Custom OEM solutions: Fast firmware adaptation enables cost-efficient implementation of customer-specific applications