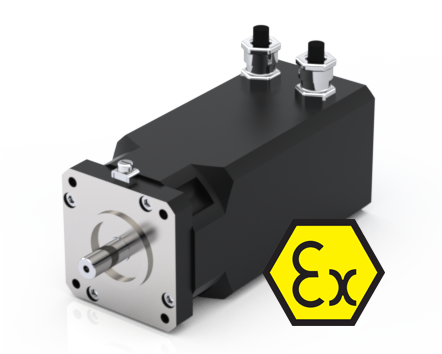

ECOSPEED 80B333-0710 ATEX, servo motor for Zones 1 and 2

Technical specifications

| Certificates | Atex , UL |

| Flange | 88 mm |

| Max. DC link voltage | 60 VDC |

| Maximum speed | 1400 rpm |

| Peak torque | 6.87 Nm |

| Stall torque | 3.35 Nm |

Overview

The ECOSPEED 80B333-0710 ATEX is a low voltage servo motor for hazardous areas that combines certified explosion protection with high torque at moderate speed. With an 88 mm flange, max. DC link voltage of 60 V DC, maximum speed of 1400 rpm, peak torque of 6.87 Nm and stall torque of 3.35 Nm, it is a strong fit for compact drive axes in ATEX Zone 1 and Zone 2.

The motor is ATEX and UL certified, so it supports approvals in regulated industries and can be used in international projects. Within the ECOSPEED 80B3x3 ATEX series, the 80B333-0710 is one of the high torque, low speed variants for 60 V supply systems. Designed for use with ECOVARIO 114D servo amplifiers, it can be integrated as part of a complete JAT drive solution.

Advantages

For machine builders, the ECOSPEED 80B333-0710 ATEX reduces the typical trade off between safety and performance.

- Certified for Zone 1 and Zone 2 operation, it avoids the need for custom enclosures or purge systems in many layouts.

- High peak torque of 6.87 Nm with 3.35 Nm stall torque gives plenty of reserve for acceleration, clamping or indexing motions at 60 V DC.

- The compact 88 mm flange keeps the axis envelope small, which helps when fitting drives into confined hazardous areas such as skids or cabinets.

- ATEX and UL certificates simplify documentation for acceptance testing and cross border projects.

Together with a matched ECOVARIO 114D amplifier, this motor forms a tested low voltage ATEX axis. Use it where you need reliable torque, clean integration and verifiable safety, then Request a concept to let JAT size the complete drive.

Where it fits

Use the ECOSPEED 80B333-0710 ATEX wherever flammable gases or vapors are present and servo grade positioning is required instead of pneumatic or hydraulic drives. Typical use cases include:

- Chemical and process skids in Zone 1 and Zone 2, for controlled rotation of valves, mixers or dosing elements.

- Printing and coating systems with solvent based media, where precise roll or drum motion is needed at moderate speeds around 1400 rpm.

- Filling and packaging equipment in hazardous areas, where compact, low voltage servo axes are preferred for safety and wiring.

- General hazardous area automation, for example drives near reactor vessels, gas handling stations or classified inspection systems.

The 60 V DC supply and high torque profile make this motor especially attractive when you standardize on low voltage ECOVARIO 114D multi axis controllers across a machine family.

Interfaces

The ECOSPEED 80B333-0710 ATEX is designed to integrate cleanly into JAT drive architectures and standard industrial wiring concepts.

- Electrical power interface

- DC link up to 60 V DC, matched to ECOVARIO 114D.

- Motor connection via trailing capable cable, typical outer diameter 8.9 mm, suitable for cable tracks in dynamic applications.

- Feedback and encoder options

- The 80B3x3 ATEX series offers incremental and absolute encoder options, so you can match the feedback type to your servo amplifier and safety concept.

- Encoder cabling is available as trailing capable cable around 10.4 mm diameter for moving axes.

- Mechanical interface

- Flange size 88 mm, shaft diameter 14 k6, designed for standard couplings and gear interfaces in this torque range.

- Load capacity supports axial loads up to 130 N and radial loads up to 250 N for typical hazardous area mechanisms in the 80B ATEX family.

- System integration

- Recommended pairing with ECOVARIO 114D 2 axis servo amplifier, 60 V DC intermediate circuit, 14 A max output current.

- Available options through the ordering form include incremental encoder, absolute encoder, holding brake and gear, so the motor can be tailored to the axis concept.