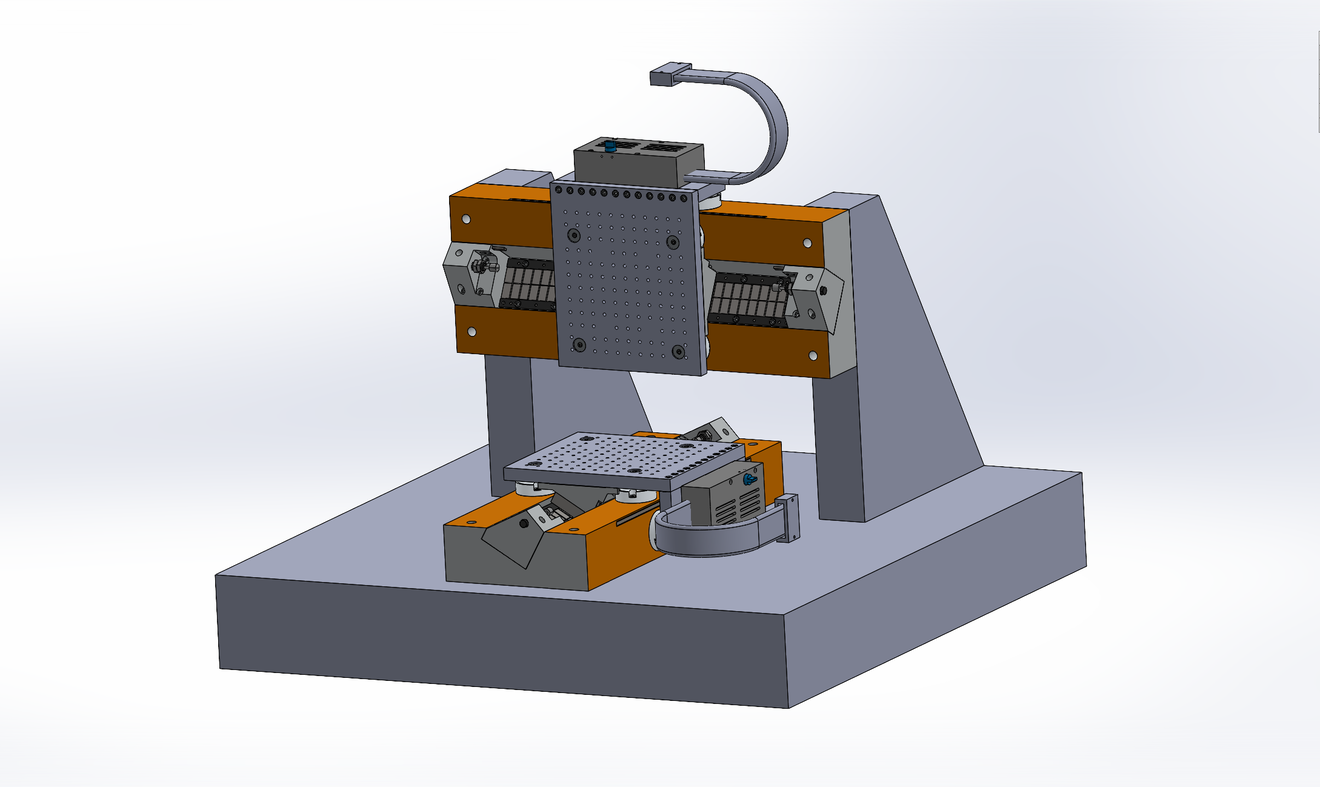

30° axis for pick & place, testing and handling

The handling of components in electronics production, wafer production and the manufacture of microchips require the highest precision. The dynamic and precise movement of workpieces on the 30° axis enables efficient and accurate processes.

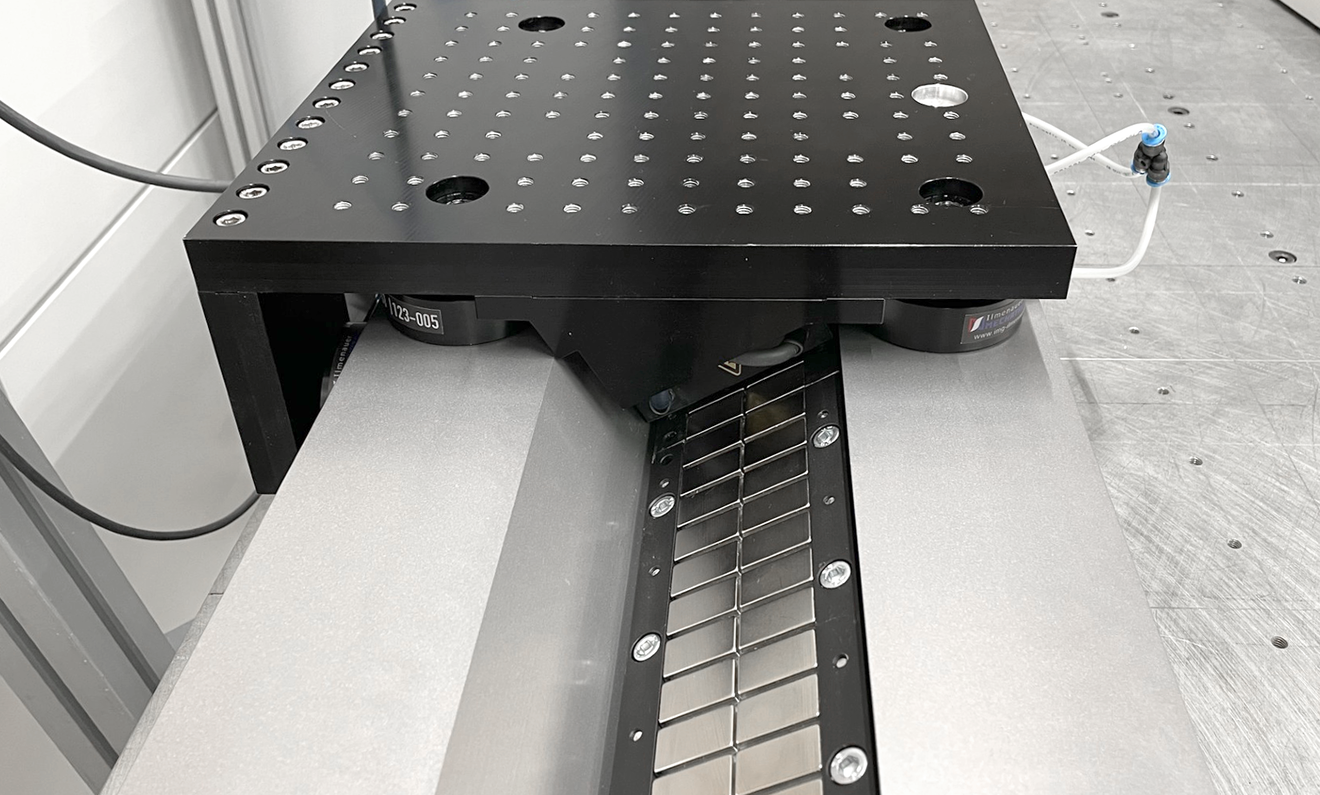

The air-bearing inclined axis is controlled by an ECOVARIO® 114D. Instead of moving over a granite, ceramic or ground steel bed, the axis moves over a finely milled aluminum bed. The iron-core motor‘s 30° inclination eliminates the need for mechanical preloading. In addition, the bearing makes the axis insensitive to thermal jamming. It is a cost-effective entry-level model for high precision.