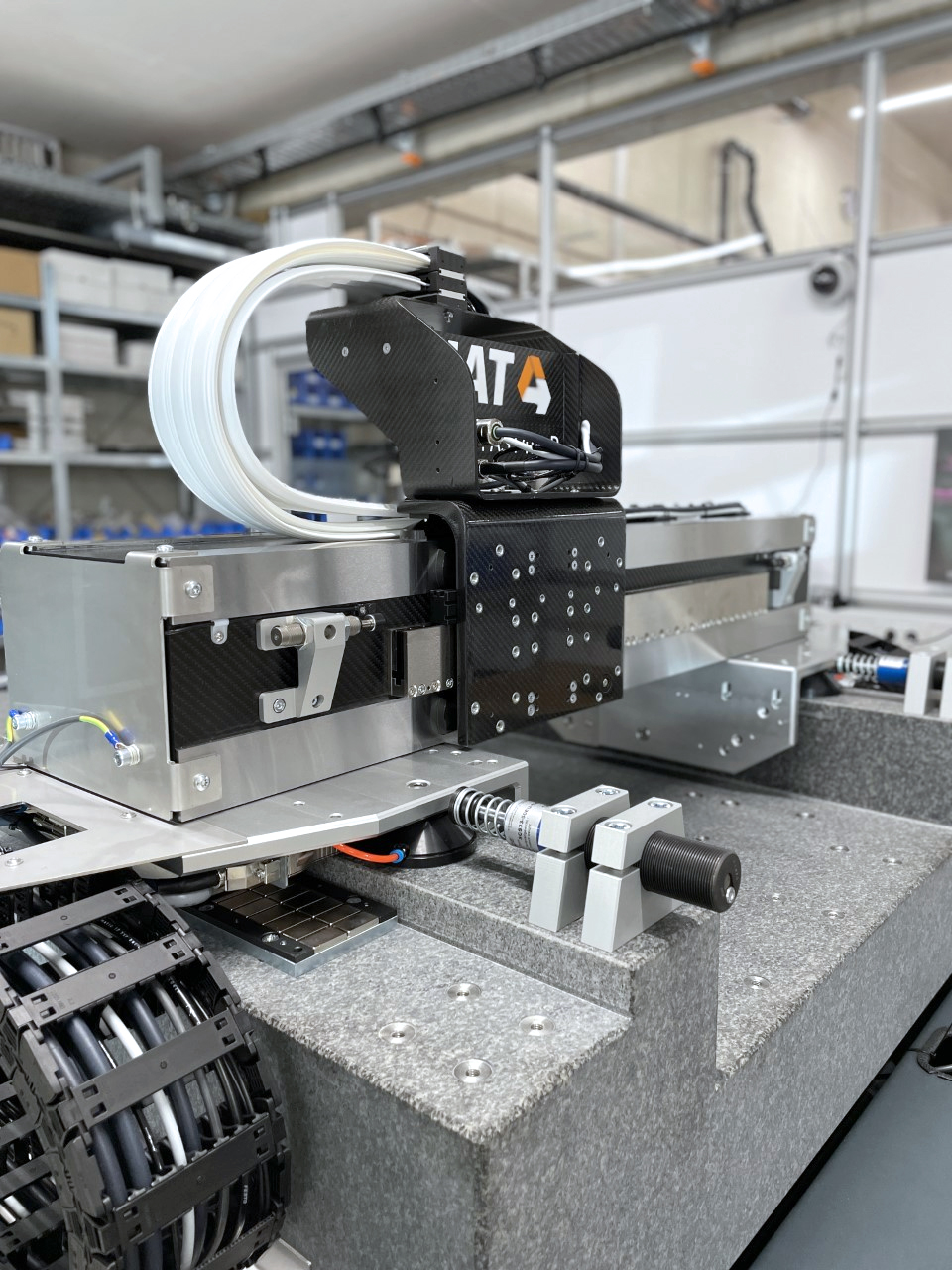

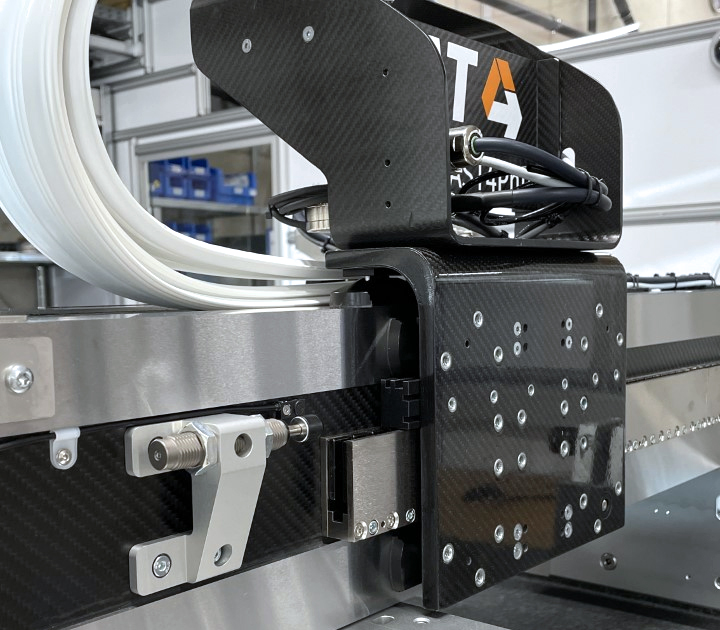

Air-Bearing Gantry-System with CFRP Axes

Request positioning solution

Depending on the application, JAT develops linear axis systems, rotary table systems and multi-axis systems. Please specify your application as far as you know it. Our drive experts will contact you with possible solutions and a cost estimate.

Combining air bearing technology with CFRP lightweight construction

The micro-electronics industry keeps pushing for tighter tolerances and higher takt times. By pairing a granite foundation with air-bearing guides and feather-light CFRP axes, JAT delivers the stiffness, damping, and speed needed for sub-micron placement accuracy. The air film eliminates stick-slip, while the reduced moving mass slashes energy draw and cycle time.

A second benefit is longevity: air bearings are wear-free and generate virtually no particles, making the system ideal for ISO 5 clean-rooms and extended 24 / 7 production without relubrication. Meanwhile, CFRP’s thermal stability helps keep dimensional drift below the nano-scale during ambient changes.

CFRP advantages

CFRP (carbon fiber reinforced plastic) enables novel axis designs that dramatically improve dynamics and precision.

Advantages

- Up to 40 % lighter than aluminium, yet stiffer - yields higher acceleration and lower power use.

- Tensile strength at ~2000 N/mm², many times greater than aluminum (190 N/mm²) and steel (490 N/mm²) and supports vibration-free motion at very high speeds.

- Conventional drive systems have a reduced productivity due to vibrations, which are compensated for via decay times and lower process speeds. CFRP makes these measures obsolete, therefore unlocking faster process speeds and higher overall productivity.

- Higher dynamics result in significant competitive advantagesin throughput without sacrificing accuracy

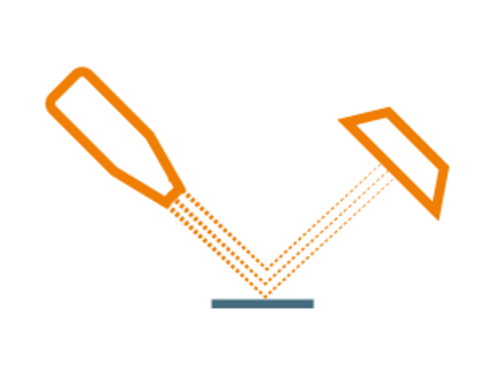

Air bearing technology advantages

Air-bearing motion systems position loads free of friction, stick-slip, and material wear, which is perfect for precision machinery and clean-room environments.

Benefits:

Frictionless, stick-slip-free, and wear-free operation

Handles very high speeds and rapid accelerations, up to 30–50 m/s linear speed in comparable stages

No oil or grease required, avoiding lubricant disposal and keeping the workspace spotless

Self-cleaning positive air pressure deters dust ingress in ISO 5 settings

Near-silent running plus minimal maintenance overhead

Enables repeatability well below 100 nm in linear or rotary configurations