High-tech materials boost productivity

Using carbon-fiber-reinforced polymer (CFRP) significantly enhances the dynamics and precision of positioning and handling systems. We demonstrate how this works using a carbon-fiber cantilever axis.

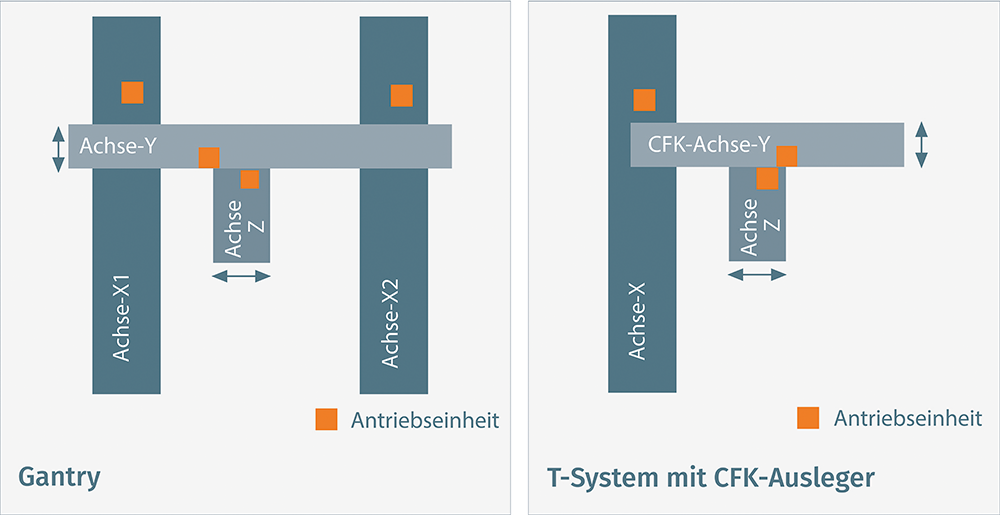

Conventional gantry systems are built from heavyweight aluminium or steel and feature dual X-axes, a Y-axis, and often a Z-axis. Each axis needs its own motor and servo amplifier, leading to complex synchronization and limited maintenance accessibility.

Integrating CFRP enables lightweight gantry designs that reduce moving mass by up to 40%, increase stiffness-to-weight by ~1.7×, and provide superior vibration damping, collectively boosting cycle speeds, positioning accuracy, and uptime.

Key technical advantages:

- Lightweight construction: Moves lighter assemblies with up to 40 % less mass

- High specific stiffness: ~1.7× stiffness-to-density ratio vs aluminium

- Superior vibration damping: Settles faster, enabling continuous high‑speed cycles

- Result: Faster cycles, nanometre-level precision, and reduced service time

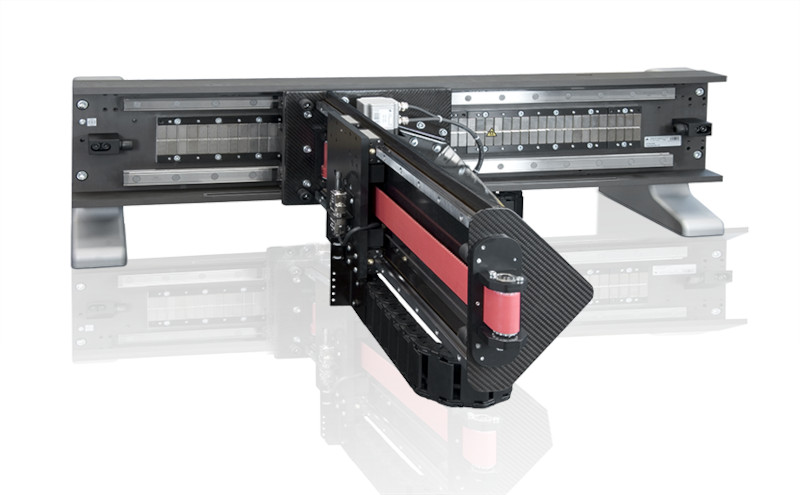

JAT (Jenaer Antriebstechnik GmbH) has been working on lightweight engineering for many years. The company designs and manufactures drive systems for automation and handling applications using carbon-fiber-reinforced polymer (CFRP) cantilever axes.

The typical setup features a T-shaped configuration. It usually consists of a linear motor axis that serves as a base and support structure for the CFRP cantilever. This novel mechanical design is only possible due to the unique properties of carbon-fiber-reinforced polymer. CFRP components are known for combining extremely low weight with very high strength. Compared to aluminum, weight savings of up to 40 percent are possible. This significant reduction in moving mass allows for much higher system dynamics, which in turn increases process speed and lowers energy consumption.

The tensile strength of CFRP reaches values of around 2,000 N/mm². That is more than four times higher than steel (approx. 490 N/mm²) and more than ten times higher than aluminum (approx. 190 N/mm²). This extremely high stiffness and strength enable vibration-free and smooth movement, even in high-speed applications. As a result, positioning accuracies in the single-digit nanometre range can be achieved reliably. This makes CFRP cantilever axes ideal for production lines that require the highest levels of precision.

In addition, conventional drive systems built with metal gantries often require dwell times to allow vibrations to settle. Alternatively, users are forced to reduce speeds to avoid unwanted oscillations. With CFRP cantilever axes, these compromises are no longer necessary. The system runs more quietly and smoothly at full speed, which increases throughput and improves process stability. Scrap caused by positioning errors is reduced to a minimum, and production becomes significantly more efficient.

T-shaped construction reduces components

The T-shaped architecture also offers economic advantages to the user. One key benefit is the reduced number of components: the second X-axis found in conventional gantry systems is no longer needed. Because the moving mass is significantly lower, smaller drive units can be used. This reduces both installation space and system costs.

The compact footprint and improved accessibility from multiple sides make integration into existing machines and systems much easier. Installation and service tasks require less effort and can be performed at longer intervals compared to traditional gantry setups.

JAT’s carbon-fiber drive systems are individually tailored to the application and are used in a wide range of production machines. For example, pick-and-place systems that move small payloads at high speed are often equipped with belt drives on the CFRP axis. For applications requiring precise and quiet movement, such as automated optical inspection (AOI), direct-drive linear technology on the CFK cantilever provides high-dynamic performance.

Another key advantage of CFRP is its excellent resistance to corrosion. This makes the drive systems an ideal fit for food processing, pharmaceutical production, and the chemical industry.

Summary

When it comes to speeding up manufacturing processes and improving product quality, composite materials are ideal due to their high mechanical and thermal load capacity. Lightweight design using CFRP has become an essential part of modern drive technology. However, it also requires a shift in design thinking, because the creation of the material and the component are closely linked, and conventional manufacturing processes often need to be adapted.

JAT customers benefit from the company’s deep expertise in the use of carbon-fiber-reinforced materials, especially in relation to application requirements, material pairing, manufacturing processes, and bonding techniques. JAT builds its series drive systems as modular kits, which means that ready-to-integrate solutions can be delivered in a short time.

Key Advantages of CFRP at a Glance

Minimal weight with maximum strength

Compared to aluminum, weight reductions of up to 40 percent are possible, without compromising structural integrity.Extremely high material strength

CFRP has a tensile strength of approximately 2000 N/mm². This is significantly higher than aluminum (190 N/mm²) and steel (490 N/mm²), enabling precise, vibration-free movement even in high-speed applications.No need for settling times or reduced speeds

Traditional drive systems often require slower speeds or dwell times to compensate for vibrations. With CFRP cantilever axes, these limitations are eliminated, allowing faster and more stable production cycles.Higher dynamics create a competitive edge

Increased motion dynamics lead to faster processes, improved throughput, and lower energy consumption—all of which offer a clear advantage in competitive manufacturing environments.